Environment Friendly Incinerators for Disposal of Industrial & Hospital Waste

LRL – D1

LRL – B40

LRL – B60

LRL – B100

| Hourly destruction capacity | Up to 10kg / hr | |

| Volume of primary chamber | 0.175m3 | |

| Volume of secondary chamber | 0.17m3 | |

| Primary chamber temperature | 800 - 900°C | |

| Secondary chamber temperature | 900 - 1050°C | |

| Secondary chamber residence time | ≥2s | |

| Fuel consumption (Diesel) | 8 I/hr | |

| Basic dimensions (H x W x L) | 670 x 470 x 610 | |

| Weight | 0.65 ton | |

| Burners | 2 | |

| Chimney Height | 2m |

| Hourly destruction capacity | Up to 30kg / hr | |

| Volume of primary chamber | 0.65m3 | |

| Volume of secondary chamber | 0.69m3 | |

| Primary chamber temperature | 800 - 900°C | |

| Secondary chamber temperature | 900 - 1200°C | |

| Secondary chamber residence time | ≥2s | |

| Fuel consumption (Diesel) | 10 - 15I/hr | |

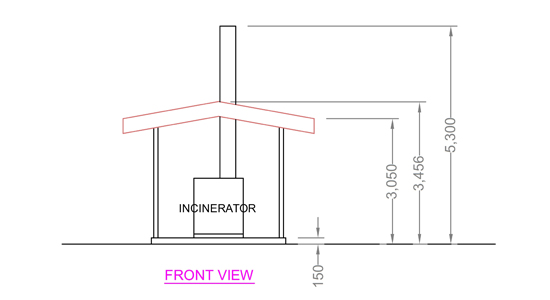

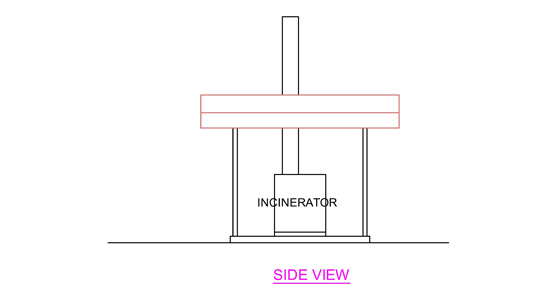

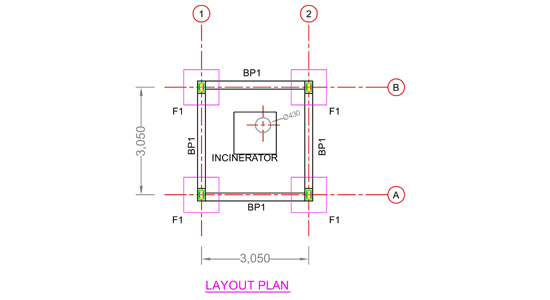

| Basic dimensions (H x W x L) | 1500 x 1500 x 1500mm | |

| Weight | ≥2 ton | |

| Burners | 2 | |

| Power supply | 230v, 50Hz |

| Hourly destruction capacity | 50 - 60kg / hr | |

| Volume of primary chamber | 1.2m3 | |

| Volume of secondary chamber | 1.86m3 | |

| Primary chamber temperature | 850 ± 50°C | |

| Secondary chamber temperature | 1200 ± 50°C | |

| Secondary chamber residence time | ≥2s | |

| Fuel consumption (Diesel) | 12 - 18It/hr | |

| Basic dimensions (H x W x L) | 2000 x 2250 x 2600mm | |

| Weight | ≥10 ton | |

| Burners | 2 | |

| Power supply | 230v, 50Hz |

| Hourly destruction capacity | 80kg / hr | |

| Volume of primary chamber | 1.5m3 | |

| Volume of secondary chamber | 2.25m3 | |

| Primary chamber temperature | 850 ± 50°C | |

| Secondary chamber temperature | 1200 ± 50°C | |

| Secondary chamber residence time | ≥2s | |

| Fuel consumption (Diesel) | 15 - 20It/hr | |

| Basic dimensions (H x W x L) | 2000 x 2250 x 2600mm | |

| Weight | ≥10 ton | |

| Burners | 3 | |

| Power supply | 230v, 50Hz |

All Incinerable Waste

Waste which are generated by Hospitals, Indrustries, Clinics, Veterinary Institutions, Research & Indrustrial

Laboratories can be diposed through our "LRL" incinerators. We undertake to manufacture incinerators to

incinerate waste such as,

Human Anatomical Waste - Human Tissues, Organs, Body Parts etc.

Animal Waste - Carcasses, Bleeding Parts, Fluids, Blood And Experimental Animals Used In Research

Aicrobiology And Biotechnology Waste - Stocks & Specimens Of Micro Organisms, Live Or Attenuated Vaccines, Human & Animal Cell Culture, Infectious Agents, Waste From Production Of Biologicals, Toxins, Dishes & Devices

Discarded Medicines & Cytooxic Drugs

Pharmaceutical And Drug Manufactures' Waste And Refuses

Solid Waste - Cotton Dressings, Solid Plaster Casts, Linens, Beddings & Other Materials

Trash / Rubbish - Papers, Cardboards, Floor Sweeps, Gunny Bags, Tea Cups, Wood Off Cut, Secret & Confidential Record

Indrustrial Waste - Paint Slug, Solvant, Insecticides, Pescticides etc.

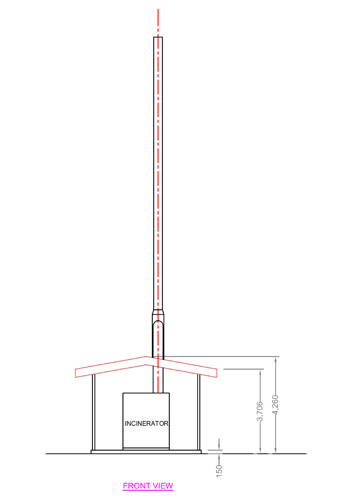

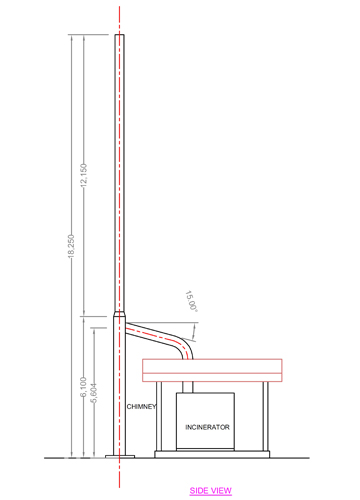

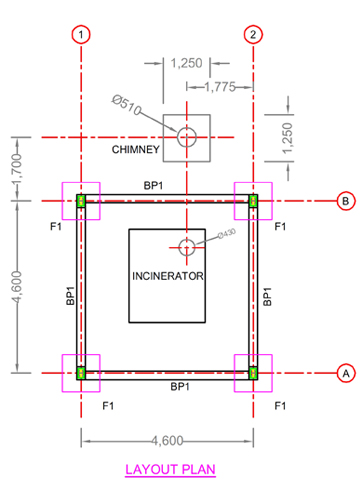

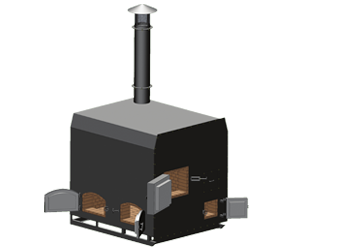

Design Features of LRL Incinerators

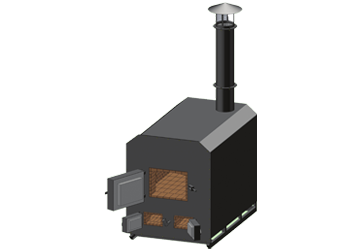

Our incinerators are dual chamber pyrolytic type. This is the most reliable type of incinerators accepted globally for incinerable waste. The incinerator contains two chambers housed in the same shell. Waste that is located in the primary chamber is burnt and the products of combustion flow across the primary chamber and enter into the secondary chamber. The flue gas passes through the core of the burner flame before emission.

Horizontal design - primary and secondary chambers are housed in single shell

Destruction efficiency is high

Handle different types of waste with moisture content of 85%

Special high alumina refractory castable providing high colding crushing strength

Operates on 230 - 250 V single phase, 50 Hz AC supply

Large loading door in primary chamber for high single charge

Separate small ash doors

Long equipment life

Construction Features

Incinerator is ruggedly build of welded and bolted steel construction

It is lined with high alumina refractory castable which gives the incinerator internal protection against

High operating temperature and extended refractory life

Coldface protection with ceramic blanket

Burner

Single pressure jet oil fired mono block burner for primary and secondary burning

Temperature requirements of 800 ± 50 °C in primary chamber and 1050 ± 50 °C or 1200 ± 50 °C in secondary chamber, can be achieved

Accessories

Diesel tank

Control panel

Refractory lined chimney

Ash rake

Additional Features

Protective thermo well for long thermo couple life

Coated stainless steel anchors for excellent bonding of refractory

High heat and corrosion resistance paint

Very low running costs

Low electric power requirement

Fuel tank refill facility

Free operator training